Product classification

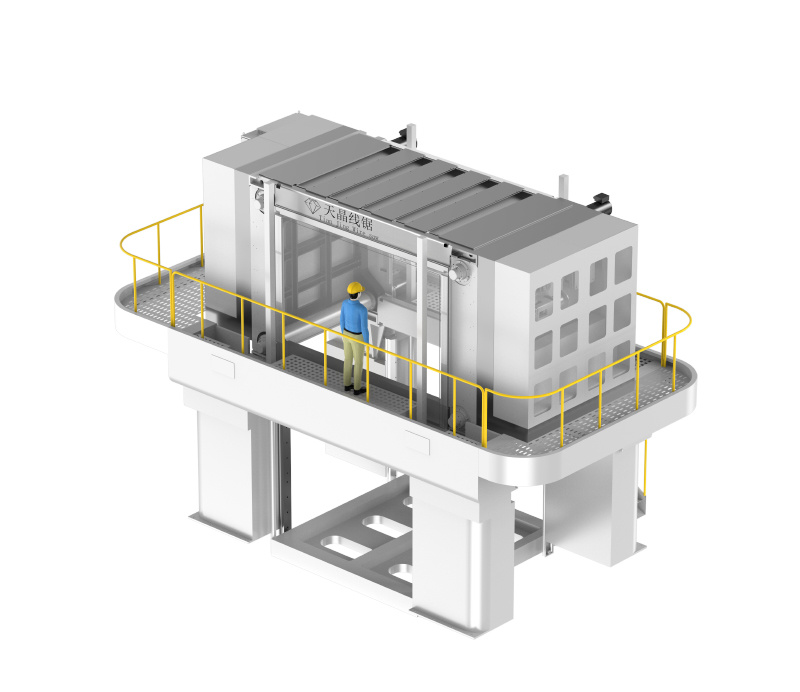

TAG320 Precision Wire Cutting Machine

The operating principle of the Precision Wire Cutting Machine is based on the EDM wire cutting technology, which uses high-speed EDM discharge to perform precision cutting on the surface of the workpiece. The device has an accurate control system, with each axis controlled by a servo bus, ensuring stable cutting quality and low cutting costs.

Classification:

Single Wire Cutting Machine Production

Key words:

TAG320 Precision Wire Cutting Machine

- Description

-

Product Working Principle

The operating principle of Precision Wire Cutting Machine is based on the EDM wire cutting technology, which uses high-speed EDM discharge to perform precision cutting on the surface of the workpiece. This process uses a fine metal wire as an electrode to produce a discharge effect with the workpiece in a liquid medium, thereby accurately removing the material. Unlike traditional cutting methods, the EDM wire cutting machine does not need to directly contact the workpiece surface, avoiding the influence of mechanical stress on the workpiece, and is particularly suitable for precision machining of cemented carbide and complex shapes.

During operation, the diamond or copper alloy electrode wire passes through the workpiece at high speed, and the current forms a high-temperature arc between the electrode wire and the workpiece surface, causing the material to partially melt and be quickly taken away by the coolant. This process can not only obtain a smooth and flat cutting surface, but also achieve extremely high cutting accuracy, ensuring that every detail is impeccable. To better meet the cutting needs of different materials, the equipment is equipped with an intelligent control system, which can automatically adjust the current, speed, and discharge interval according to different material properties and cutting requirements.

In addition, the Precision Wire Cutting Machine has an excellent heat dissipation system, which effectively controls the heat generated during the cutting process and ensures that the equipment can operate efficiently for a long time. The liquid medium used in the cutting process not only plays a cooling role, but also effectively removes tiny particles in the cutting process, keeping the cutting surface clean and precise.

The working principle of the Precision Wire Cutting Machine is simple and efficient, suitable for various precision manufacturing and processing needs. Whether it is a complex-shaped part or a hard material, this cutting machine can provide you with excellent precision and extraordinary cutting results, helping your production line improve efficiency and quality.

Previous Page

Next Page

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.