Product classification

TJ6060 Three-Station Single-Line Cutting Machine

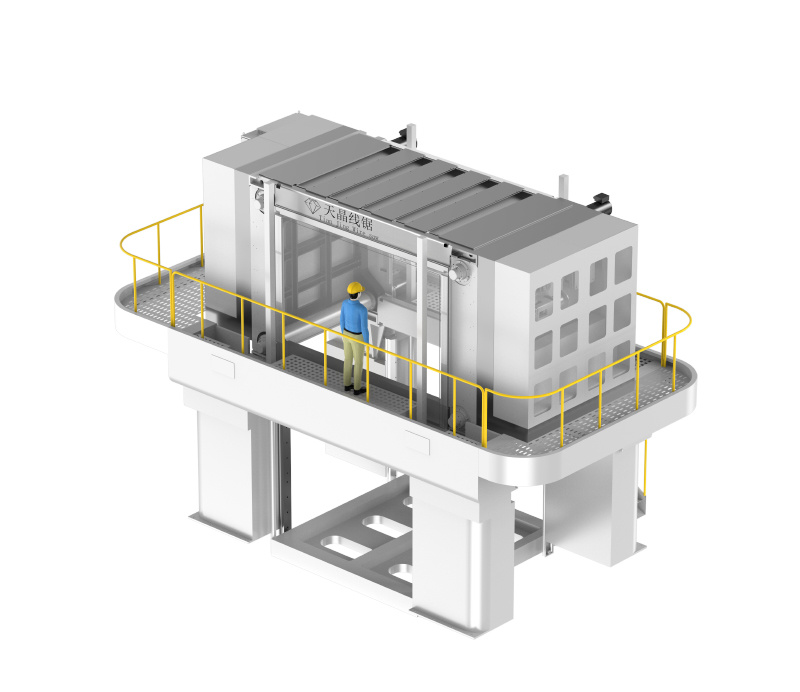

The three-station single-line cutting machine is mainly used for the processing of hard and brittle materials such as sapphire, jade, and emerald. It utilizes the high-speed reciprocating motion of a diamond wire with diamond particles to cut the sapphire material in the processing area, thereby transforming large materials into smaller ones, resulting in high production efficiency, high product quality, low processing costs, high control precision, and environmentally friendly advantages.

Classification:

Single Wire Cutting Machine Production

Key words:

TJ6060 Three-Station Single-Line Cutting Machine

- Description

-

Product Overview

The three-station single-line cutting machine is mainly used for the processing of hard and brittle materials such as sapphire, jade, and emerald. It utilizes the high-speed reciprocating motion of diamond wire with diamond particles to cut the sapphire material in the processing area, thereby transforming large materials into small ones, resulting in high production efficiency, high product quality, low processing costs, high control precision, and environmentally friendly advantages.

Product Features

●The overall structure layout design: The design is divided by function, separating the main cutting area from the wire operation area, providing a good working environment for the wire system, and allowing open operation in the cutting area for easy operation and maintenance.

●The wire feeding, wire collection, wire arrangement, spindle operation, cutting wire tension, and workbench feeding are all driven and controlled by servo motors.

●The tension control for wire feeding and collection adopts a closed-loop feedback control method, ensuring the constant tension of the cutting wire during the cutting process.

●It also has a tension warning function, effectively avoiding wire breakage failures caused by abnormal tension fluctuations.

●All series of Tianjing products are equipped with intelligent devices that have cloud systems, remote monitoring, and maintenance functions, providing customers with the fastest and safest after-sale service, making usage simpler!

Technical Parameters

Project

Unit Parameter Maximum Workpiece Size

mm ø600*600 Workbench Vertical Lifting Stroke

mm 800 Cutting Speed

mm/hour 400-1200 Wire Running Speed

m/min 1000(max)

Diamond Wire Diameter

mm 0.25-0.48 Wire Feeding Wheel Storage Amount

km 20 Cutting Thickness Range

mm 0-800 Power Source

Three-phase four-wire AC380V/50Hz

Total Power of Machine Tool

KW ≤23

Wire Collection and Feeding Motor

KW 5.5X2 units Workbench Motor

0.4X2 units Wire Arrangement Motor

0.4X2 units Tension Control Motor

3.0X2 units Cutting Motor

0.4X6 units Acceleration Motor

0.4X2 units Dimensions

mm 6000*2000*2000 Machine Weight

Kg About 4000KG

Previous Page

Next Page

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.