Why Is High-End Manufacturing Increasingly Dependent on Sapphire Cutting Machine

Time:

2025-05-19

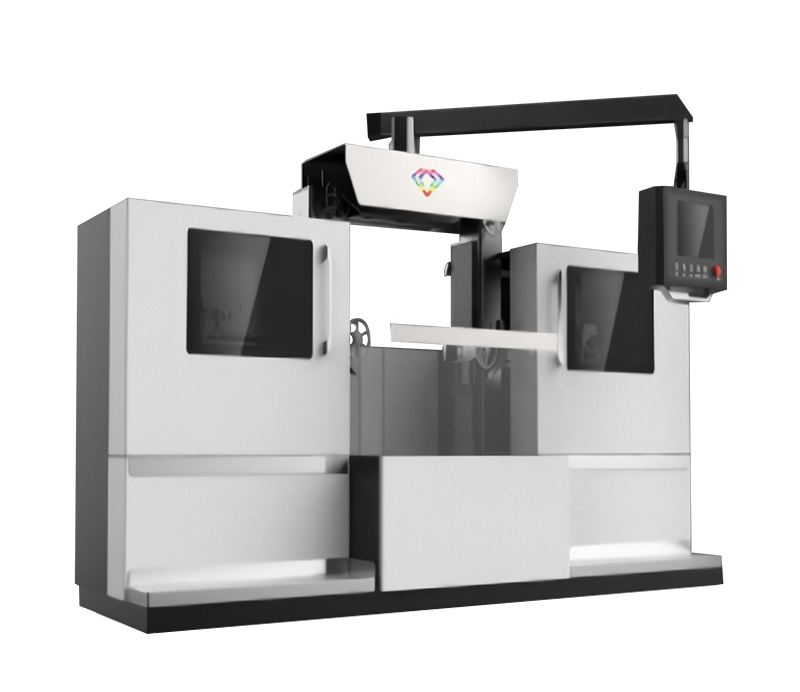

Sapphire, a material with hardness second only to diamond, is widely used in high-end watch mirrors, optical windows, semiconductor substrates, and even aerospace equipment. However, due to its high hardness and brittleness, it is extremely difficult to cut. The birth of the Sapphire Cutting Machine is a breakthrough response to the processing technology of this type of high-performance material - it can not only cut, but also cut accurately and elegantly.

This cutting machine uses laser-assisted micro-cutting technology and a multi-axis CNC system, equipped with a high-frequency vibration cooling system, which effectively avoids micro-cracks caused by high temperature during cutting. At the same time, the introduction of an AI path optimization algorithm can automatically adjust the feed angle according to the sapphire crystal structure to achieve sub-millimeter error control, thereby greatly improving the yield rate and the edge finish of the finished product.

Sapphire Cutting Machine responds to the processing challenges of superhard materials in an "actuarial + intelligent" way. It not only promotes the material upgrade in the fields of consumer electronics and advanced manufacturing, but is also becoming the "invisible giant force" behind industries such as wafer manufacturing and new energy equipment. The edge of science and technology is being cut out from sapphires.

RELATED INFORMATION