The Benefits of a New Three-Station Multi-Wire Cutting Machine

Time:

2025-07-15

1. Introduction to Multi-Wire Cutting Technology

The landscape of industrial manufacturing is continuously evolving, and **multi-wire cutting technology** stands at the forefront of this transformation. As industries demand higher output and precision, the **three-station multi-wire cutting machine** emerges as a crucial player, offering remarkable efficiencies and capabilities. This article explores how this innovative technology can significantly enhance your operations.

2. What is a Three-Station Multi-Wire Cutting Machine?

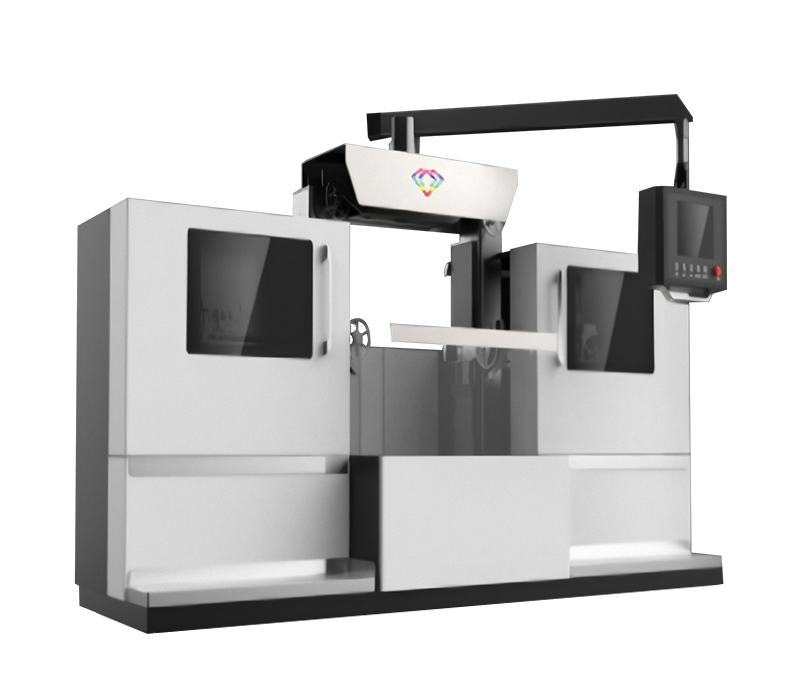

A **three-station multi-wire cutting machine** is a sophisticated piece of equipment designed to cut materials with multiple wires simultaneously. This technology allows for the cutting of various materials, including metals and composites, through a series of interconnected wire saws. Each station operates in harmony, leading to enhanced productivity and reduced cycle times, making it ideal for industries such as automotive, aerospace, and electronics.

3. Advantages of Using Multi-Wire Cutting Machines

The implementation of a three-station multi-wire cutting machine brings a myriad of advantages that can significantly improve your manufacturing process. Below, we delve into the core benefits.

3.1 Increased Productivity

One of the most compelling benefits of a three-station machine is its ability to **increase productivity**. By cutting multiple pieces simultaneously, manufacturers can produce more parts in less time. This efficiency translates to shorter lead times and the ability to meet growing market demands without compromising quality.

3.2 Cost Efficiency

Investing in a three-station multi-wire cutting machine can lead to improved **cost efficiency**. As production speeds increase, labor costs decrease due to reduced operator involvement per part produced. Additionally, the machine's capability to minimize material waste further enhances its cost-effectiveness, making it a sound investment for manufacturers.

3.3 Precision and Quality

In industries where **precision** is paramount, the three-station cutting machine excels. This technology ensures uniform cuts with minimal kerf loss, significantly enhancing the quality of the final product. With advanced control systems, operators can achieve consistent results, leading to fewer defects and higher customer satisfaction.

3.4 Versatility in Applications

The versatility of a three-station multi-wire cutting machine makes it suitable for diverse applications. Whether it’s cutting intricate components for the aerospace industry or performing bulk cuts for automotive parts, this technology adapts to various materials and applications, ensuring that it meets the unique needs of different sectors.

4. Technical Aspects of Three-Station Machines

Understanding the technical specifications of a three-station multi-wire cutting machine can help businesses leverage its full potential. These machines typically feature advanced **CNC (Computer Numerical Control)** systems that allow for precise programming and operation. Key technical aspects include:

- **Cutting Speed**: The speed at which the cutting wires operate significantly affects productivity. Modern machines often feature adjustable speeds to suit various materials.

- **Wire Tension Control**: Effective tension control is vital to prevent wire breakage and ensure optimal cutting performance.

- **Cooling Systems**: Integrated cooling systems reduce heat buildup during cutting, prolonging the life of the wires and enhancing cutting efficiency.

5. Operational Benefits

The operational benefits of a three-station multi-wire cutting machine extend beyond mere productivity. They include:

- **Reduced Downtime**: With fewer machine adjustments required due to the efficiency of multi-wire systems, downtime is minimized. This allows for continuous production and maximizes overall equipment effectiveness.

- **Enhanced Operator Safety**: Modern machines often incorporate safety features that protect operators during operation, reducing the risk of accidents in the workplace.

6. Maintenance and Reliability

Maintaining a three-station multi-wire cutting machine is crucial for ensuring long-term reliability. Regular maintenance schedules, including wire replacement and system calibration, can prevent unplanned downtime. Many machines now incorporate self-diagnostic tools, alerting operators to potential issues before they escalate into significant problems. This proactive approach to maintenance ensures consistent performance and reliability.

7. Case Studies

Numerous companies have successfully integrated three-station multi-wire cutting machines into their operations, resulting in significant improvements. For instance, **ABC Manufacturing** reported a **30% increase in production capacity** after adopting this technology, allowing them to take on larger contracts and increase their market share. Similarly, **XYZ Composites** noted a **40% reduction in material waste**, leading to substantial cost savings and enhanced environmental sustainability.

The introduction of a **three-station multi-wire cutting machine** into your manufacturing process represents a significant step toward enhanced efficiency and productivity. With its ability to cut multiple materials simultaneously, reduce costs, and improve product quality, this advanced technology stands out as a vital asset for modern industries. By investing in such equipment, businesses not only stay competitive but also position themselves for future growth and innovation. Embracing this cutting-edge technology will undoubtedly pave the way for a more productive and efficient manufacturing environment.

RELATED INFORMATION