Product classification

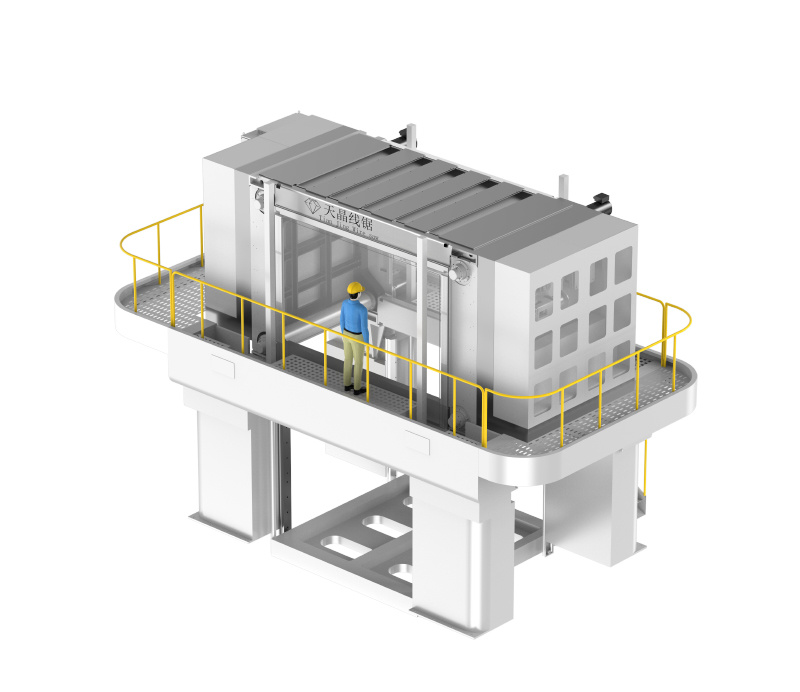

Tanzanite Ceramic Rod Machine

Tanzanite Ceramic Rod Machine is a high-precision equipment designed for the field of ceramic processing. It is mainly used for cutting, forming, and precision processing of ceramic rods. This equipment adopts advanced technology and a precision control system, and realizes rapid processing of ceramic rods through efficient automated production lines.

Classification:

Poking Machine Production

Key words:

Tanzanite Ceramic Rod Machine

- Description

-

Tanzanite Ceramic Rod Machine is a high-precision equipment designed for the field of ceramic processing. It is mainly used for cutting, forming, and precision processing of ceramic rods. This equipment adopts advanced technology and a precision control system, and realizes rapid processing of ceramic rods through efficient automated production lines. It is not only suitable for traditional ceramic processes, but also widely used in the production of new ceramic materials.

In terms of usage advantages, the Tanzanite Ceramic Rod Machine has shown many significant features. First of all, the equipment has strong processing capabilities and extremely high precision, which can ensure that the cutting size of ceramic rods is accurate, the surface is smooth and burr-free, and it can meet the processing needs of various complex shapes. Secondly, it is also equipped with an intelligent control system with a simple and clear operation interface, which reduces manual intervention while also improving production efficiency. The stability and efficiency of the machine greatly shorten the production cycle and reduce production costs. In addition, the machine has a high degree of automation and can work 24 hours a day to meet large-scale production needs.

Tanzanite Ceramic Rod Machine brings significant economic and technical value to customers. First of all, the high efficiency and high precision of the equipment mean that customers can complete more orders at a lower production cost, improving overall output value and market competitiveness. Secondly, due to its high degree of automation and simple operation of the equipment, it can reduce labor costs and human operating errors, thereby improving production safety.

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.