Product classification

Sapphire components

Sapphire components are increasingly used in today's society. With the development of modern science and technology, sapphire non-metallic materials have found applications in various industries. Most people are well aware of the applications of sapphire and use it to make components for their own industries. One important advantage of sapphire is its hardness, which makes it suitable for serving as components to support the core of machines.

Classification:

Sapphire optical components

Key words:

Sapphire components

- Description

-

Product Overview

Sapphire components are increasingly used in today's society. With the development of modern science and technology, sapphire non-metallic materials have found applications in various industries. Most people are well aware of the applications of sapphire and use it to make components for their industries. One important advantage of sapphire is its hardness, which allows it to serve as components to support the core of machines. Although sapphire has some special properties, it is relatively difficult to process, and making components from it is even more challenging. In fact, the processing technology for sapphire parts is kept confidential internationally, and outsiders are unaware of it. The main difficulty in processing lies in controlling surface quality, specifically how to avoid the presence of pits and marks during the processing. A slight mistake can lead to failure in the processing, resulting in certain losses. Additionally, it must meet corresponding standards before it can be sold, ensuring size precision and smoothness, which are key technical aspects of processing. This is especially critical in the polishing process, as it directly affects the surface quality of the components. Therefore, high-speed fine grinding must be employed, combining fine grinding and rough grinding to improve the roughness of the component's surface after fine grinding, thus creating favorable conditions for polishing. When such components are completed, they are perfect, meeting standards in both quality and precision, allowing them to be sold directly.

Previous Page

Next Page

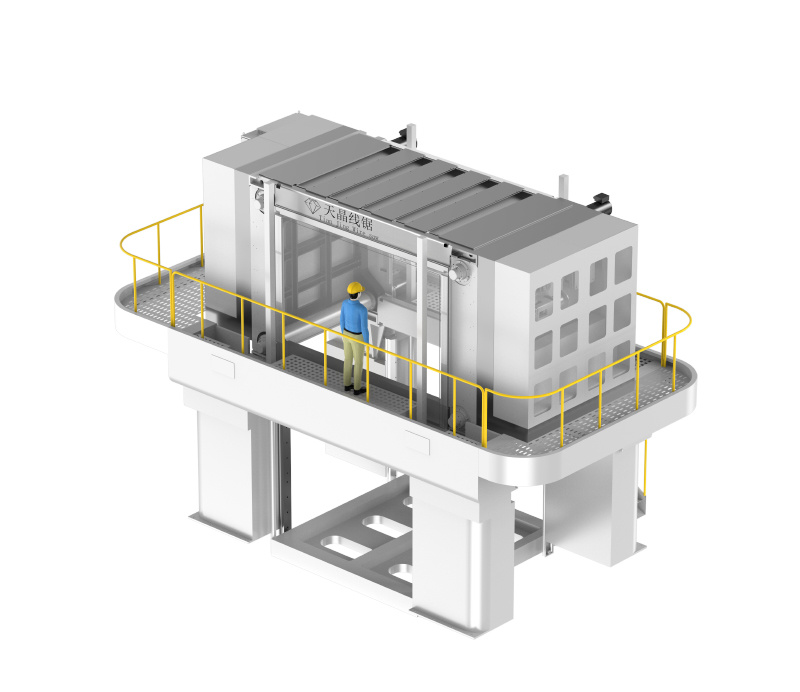

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.