Product classification

Endoscope

Endoscopes were first used in the medical field, primarily for inspecting the internal structures of industrial machinery. To provide certain protection for the endoscope and prevent damage, most endoscope protective covers are made using sapphire technology, based on the strong hardness of sapphire.

Classification:

Medical beauty equipment accessories

Key words:

Endoscope

- Description

-

Product Overview

Endoscopes were first used in the medical field, primarily for inspecting the internal structures of industrial machinery. To provide a certain level of protection for the endoscope and prevent damage, most endoscope protective covers are made from sapphire due to its strong hardness. During the inspection of mechanical structures, these covers prevent collisions and friction that could damage the endoscope's structure. This device was invented by French doctor Desomieux and has continued to evolve to this day. With the advancement of science and technology, and through several generations of technological transformation, we have achieved the current state of endoscopes, which has fundamentally changed the concept of endoscopy and opened a new era for it. During the inspection process, most mechanical environments are either high-temperature or toxic, and the spaces within mechanical tools are often very narrow. To enable the endoscope to operate in such harsh environments, sapphire protective covers are essential. High temperatures do not affect sapphire, it is not corroded by toxins, and it is not damaged by collisions or friction in tight spaces. It can be said that this protective cover is indeed a wise choice, facilitating the recording of internal conditions of equipment and making it easier to locate maintenance areas. Due to its high characteristics, sapphire has become a common phenomenon in the application of endoscope protective covers, serving a protective role due to its inherent hardness.

Previous Page

Next Page

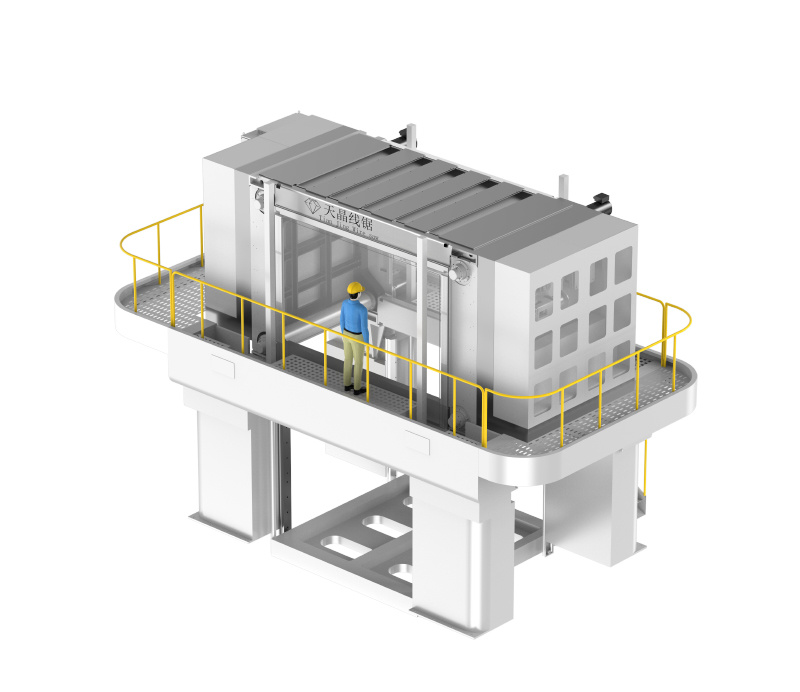

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.