Product classification

Semiconductor Applications

The application range of sapphire optical components is very broad, one of which is in the semiconductor industry. Most sapphires are in crystal form, which is very suitable for making optical components. The semiconductor is composed of many different materials, and sapphire is one of the highly needed ones. This type of sapphire crystal material can be used to create optical components of various sizes and different shapes and orientations, and these optical components are non-scattering, making them very suitable for semiconductor applications.

Classification:

Sapphire optical components

Key words:

Semiconductor Applications

- Description

-

Product Overview

The application range of sapphire optical components is very broad, one of which is its application in the semiconductor industry. Most sapphires are in crystal form, which is very suitable for making optical components. The semiconductor is composed of many different components, and sapphire is one of the highly needed materials. This type of sapphire crystal material can be used to create optical components of various sizes and different shapes and orientations. Moreover, these optical components are non-scattering, making them very suitable for semiconductor applications. Some sapphire crystals have very different characteristics, capable of covering strong ultraviolet rays or other types of infrared intrusion. If such optical components are applied in the semiconductor industry, they possess ultra-high hardness characteristics, high transmittance, as well as high chemical reaction stability and thermal stability, encompassing all the advantages of optics, physics, and chemistry. They have been widely used in fields such as aerospace and industry. For example, many semiconductor materials in the industry contain sapphire optical component elements. Although it is so excellent, it has not been developed and applied in some finer fields, possibly due to certain limitations. However, in large-scale industries, it can still demonstrate its advantages.

Next Page

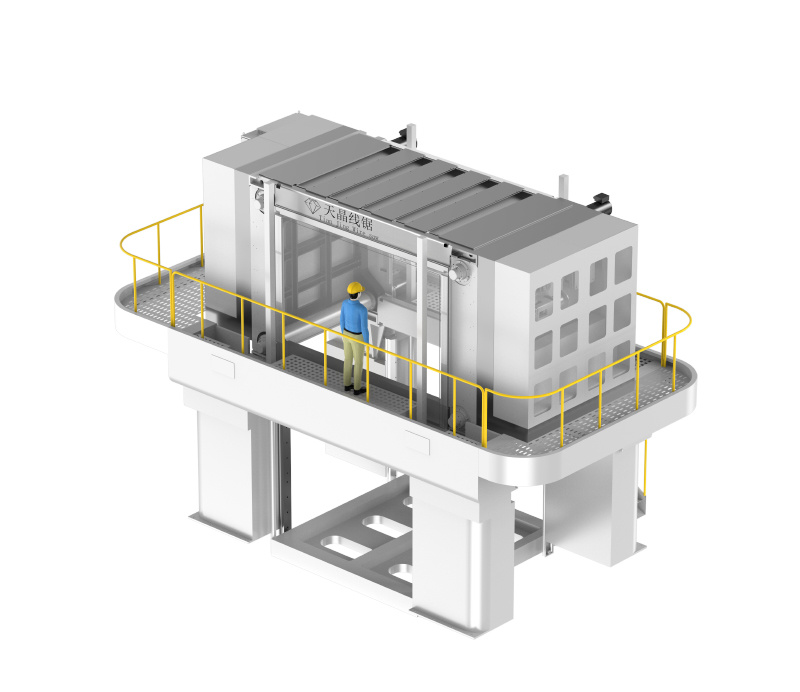

The main advantages of Tianjing equipment

Our goal is to achieve win-win

High precision

With high-precision cutting ability, it can achieve precise cutting of various materials to ensure product quality and production efficiency.

Oversized

With a large size cutting range, it can meet the cutting needs of different sizes of products and improve production efficiency.

multi-line cutting

Support multi-line cutting function, can carry out multiple cutting tasks at the same time, improve production efficiency.

Stability

With stable working performance, it can maintain a stable cutting effect in long-term operation and reduce the possibility of failure.

Easy operation

With a simple and easy-to-use operation interface, it is convenient for operators to set parameters and operate control, and improve production efficiency.

Security

Have perfect safety protection measures to ensure the safety of operators and reduce the occurrence of accidents.

Want to know more product information?

Leave your contact information to obtain the latest quotation information of the product.